We have gained confidence and records in various sectors from a traditional craft to a core industry such as containers of cosmetics, cars, electric appliances or telecommunication devices.

WASHIN COAT (former PLUS COAT) can provide functionalities and colors to the surface of each plastic film like PET and of metallization as a coating for plastic film. It has evaluated in long term by various sectors such as a metallic yarn, a stamping foil, a transfer foil, and so on, for a long time.

It is developed for transfer foil with hot stamping, for example gold and silver foil or printed foil.

We assort a set of product required in release layer, protective and coloring layer, and sizing layer.

Every product is able to select and combine according to your requirement.

| Use | Type | Product name | Feature | Solid content |

|---|---|---|---|---|

| Release layer (one layer) |

two-pack | TF - 1001 | good adherability to film | 10.0% |

| CAT - 1 | 75.0% | |||

| one-pack | TF - 1101 | gas cushion | 0.6% | |

| one-pack | TF - 1201 | light release type | 5.0% | |

| one-pack | TF - 1202 | good solvent resistance | 10.0% | |

| Release layer (two layer-1) |

one-pack | TF - 1101 | gas cushion | 0.6% |

| one-pack | TF - 1102 | good surface slippery | 2.5% | |

| one-pack | TF - 1103 | overstampability | 3.1% | |

| Release layer (two layer-2) |

one-pack | TF - 1201 | light release type | 5.0% |

| one-pack | TF - 1202 | good solvent resistance | 10.0% | |

| one-pack | TF - 1203 | better definition than TF - 1202 |

14.3% | |

| Protective and coloring layer |

two-pack |

TFH - 2001 | foil for plastic / for coloring | 47.0% |

| CAT - 2 | 97.0% | |||

two-pack |

TFH - 2002 | foil for paper / for coloring | 50.0% | |

| CAT - 2 | 97.0% | |||

| Corrosion prevention layer | one-pack | TF - 4001 | corrosion prevention for tin metalizing |

5.0% |

| Sizing layer | one-pack | TFH - 5001 | for styrene substrates (ABS / AS / PS) |

28.0% |

| one-pack | TFH - 5002 | 36.0% | ||

| one-pack | TFH - 5003 | 36.0% | ||

| one-pack | TFH - 5004 | for PET / UV thermal hardening varnish |

20.0% | |

| one-pack | TFH - 5005 | for PMMA / PC / second surface foil | 34.0% | |

| one-pack | TFH - 5006 | for PP substrates | 14.0% | |

| one-pack | TFH - 5007 | 11.0% | ||

| one-pack | TFH - 5008 | for general plastic | 16.0% | |

| one-pack | TFH - 5009 | for multi-color printing foils | 19.0% | |

| one-pack | TFH - 5010 | for UV / thermal hardening varnish | 31.0% | |

| one-pack | TFH - 5011 | for PE / PVC substrates | 14.0% | |

| one-pack | TFH - 5012 | for PET / substrates | 22.0% | |

| two-pack | TFH - 5013 - 1 | for laminated PP / general coated paper | 45.0% | |

| TFH - 5013 - 2 | 18.0% |

It id developed for in-molding foil which is used for the molding system of stimultaneous transcription.

We assort a set of product required in release layer, UV hard coat layer, varios middle layers, and sizing layer,

Every product is able to select and combine according to your requirements.

| Use | Type | Product name | Feature | Solid content |

|---|---|---|---|---|

| Release layer (one layer) | two-pack | TF - 1001 | film adhesion type | 10.0% |

| CAT - 1 | 75.0% | |||

| one-pack | TF - 1102 | good surface slipping property | 2.5% | |

| UV hard coat layer | two-pack | TFM - 2101 | heat-precure / post UV cure type | 53.0% |

| CAT - 3 | 0.5% | |||

| one-pack | TFM - 2102 | heat-precure / post UV cure type | 33.0% | |

| First primer layer | two-pack | TFM - 3101 A | Improvement of adherability to hard coat lager < yellowing type> |

40.0% |

| TFM - 3101 B | 37.0% | |||

two-pack |

TFM - 3102 A | Improvement of adherability to hard coat lager <non-yellowing type> |

40.0% | |

| TFM - 3102 B | 33.0% | |||

two-pack |

TFM - 3103 A | Improvement of adherability to hard coat lager One coat application *with printability |

40.0% | |

| TFM - 3103 B | 35.0% | |||

| Second primer layer | one-pack | TFM - 3201 | Good Printability | 29.0% |

| Primer layer for metalization | two-pack | TFM - 3101 A | yellowing type | 40.0% |

| TFM - 3101 B | 37.0% | |||

| two-pack | TFM - 4101 A | yellowing type | 35.0% | |

| TFM - 4101 B | 34.0% | |||

| two-pack | TFM - 4102 A | non-yellowing type | 40.0% | |

| TFM - 4102 B | 25.0% | |||

| Anchoring layer on metalization | one-pack | (TFM - 5101) | good adherability to metalization | 30.0% |

| one-pack | (TFM - 5102) | chlorine - free type | 20.0% | |

| Sizing layer | one-pack | TFM - 5101 | good adherability to substrates | 30.0% |

| one-pack | TFM - 5102 | chlorine - free type | 20.0% | |

| one-pack | TFM - 5103 | chlorine - free type | 32.0% |

It is developed for metalized PET film for metalic yarn.

It is superior in adhesion to the surfece of PET film and that of metalizaion layer.

It is anabled to use for purpose other than metalic yarn, because it has properties to endure hard circumstances.

Example; launderability

| Metal | Type | Product name | Feature | Solid cotent |

|---|---|---|---|---|

| Al | one-pack | MP - 6001 | for coloring | 45.0% |

| one-pack | MP - 6002 | for coloring | 46.0% | |

| one-pack | MP - 6003 | corrosion prevention of aluminun metalization layer | 29.0% | |

two-pack |

MP - 6004 A | for deep color | 36.0% | |

| MP - 6004 B | 43.0% | |||

three-pack |

MP - 6005 A | for metallic yarn / post-staining resistance | 36.0% | |

| MP - 6005 B | 43.0% | |||

| CAT - 5 | 30.0% | |||

two-pack |

MP - 6006 A | low-formaldehyde | 55.0% | |

| MP - 6006 B | 34.0% | |||

| three-pack | MP - 6007 A | for metallic yarn / high pressure staining resistance | 64.0% | |

| MP - 6007 B | 33.0% | |||

| MP - 6007 C | 34.0% | |||

| additive | ADD - 1 | add slippery | 37.0% | |

| additive | ADD - 2 | add slippery | 10.0% | |

| Ag | one-pack | MP - 6101 | transparence coat | 25.0% |

| one-pack | MP - 6102 White | white coat | 16.0% | |

two-pack |

MP - 6103 A | transparence coat | 40.0% | |

| MP - 6103 B | 30.0% | |||

| three-pack | MP - 6104 A | transparence coat | 15.0% | |

| MP - 6104 B | 22.0% | |||

| CAT - 4 | 50.0% | |||

| three-pack | MP - 6105 | white coat | 31.0% | |

| MP - 6105 White | 25.0% | |||

| CAT - 5 | 30.0% |

It is developed for various fanctional film.

It is superior in hardness and adhesion to base material.(mainly PP)

It is selectable according to the needs of functionality and property required.

| Function | Type | Product name | Feature | Solid cotent |

|---|---|---|---|---|

| Hardness | UV / one-pack | FN - 7001U | good adherability to PET | 80.0% |

| Semi-hard for untreated PET | UV / one-pack | FN - 7002U | good adherability to untreated PET | 68.0% |

| Antiblocking | UV / one-pack | FN - 7101U | 50.0% | |

| UV / one-pack | FN - 7102U | 55.0% | ||

| Printablity | UV / one-pack | FN - 7201U | adhesion to treated PET film | 75.0% |

| Anti-pollution | UV / one-pack | FN - 7301U | contact angle : 102.8° / Water | 55.0% |

| Anti-finger print | UV / one-pack | FN - 7401U | 60.0% |

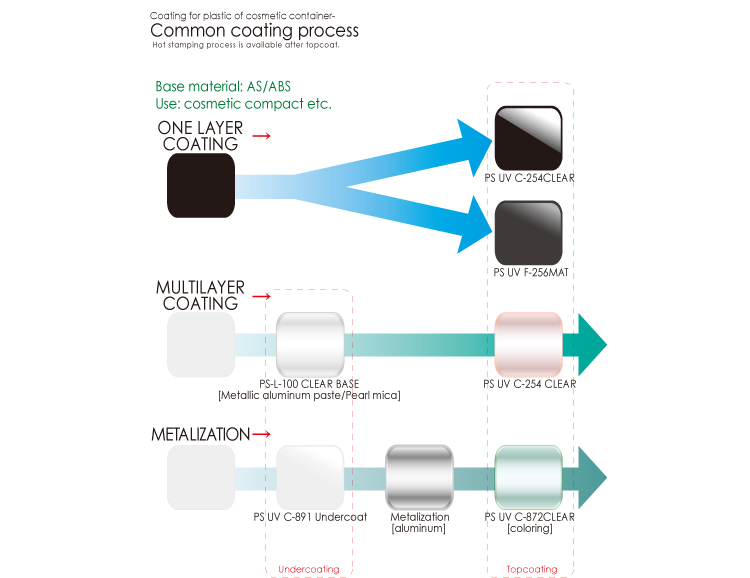

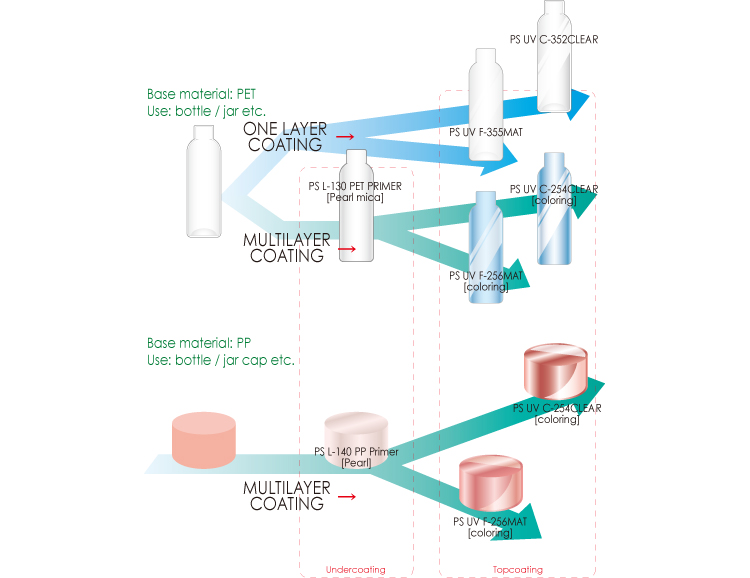

As a coating for plastic moldings, POLYSTER provides function to each plastic substrate such as PET, ABS, AS, PC, or PP for cosmetic containers or home electrical appliances. Also, it has good secondary workability to bring more luxurious image to plastic moldings by transcript of foil. The coating gives care to environment or workability because it is UV curing type.

| Use | Base material | Product name | Feature |

|---|---|---|---|

| Finishing | AS / ABS | POLYSTER UV C-231 CLEAR | hard coat |

| POLYSTER UV C-252 CLEAR | good stampability | ||

| POLYSTER UV C-254 CLEAR | semi-hard for plastic | ||

| PET | POLYSTER UV C-352 CLEAR | semi-hard for PET | |

| Frost fiishing | AS / ABS | POLYSTER UV F-256 MAT | frost finishing |

| PET | POLYSTER UV F-355 MAT | frost finishing | |

| Special functionality | AS / ABS | POLYSTER UV C-721 CLEAR | anti-pollution |

| AS / ABS | POLYSTER UV C-733 CLEAR | anti-finger print |

| Use | Base material | Product name | Feature |

|---|---|---|---|

| Basecoat for coloring |

- | POLYSTER L-100 CLEAR BASE | one-pack basecoat |

Primer for |

PP | POLYSTER L-140 PP primer | halogen - free |

| PET | POLYSTER L-130 PET primer | primer for PET |

| Use | Base material | Product name | Feature |

|---|---|---|---|

Metalization |

AS / ABS | POLYSTER UV C-872 CLEAR | topcoat for metalization |

| AS / ABS | POLYSTER UV C-891 UNDERCOAT | basecoat for metalization |

| Use | Base material | Product name | Feature |

|---|---|---|---|

|

Thinner for dilution |

- | POLYSTER UV No.25 Thinner | mild solvent type |

| POLYSTER UV No.33 Thinner | UV paint for PET | ||

| POLYSTER No.101 Thinner | dedicated / L-100 clear base | ||

| POLYSTER No.141 Thinner | dedicated / L-140 PP primer | ||

| POLYSTER No.131 Thinner | dedicated / L-130 PET primer |

Special Primer improves the adherability to substrates which doesn’t easily adhere, such as plastic, metal or coating surface. We will pursue a possibility of adherability more and more through the special primer for improvement of adhesion.

| Product name | Base material | Detail | Feature | Usage Example |

|---|---|---|---|---|

| TFM - 4101 (yellowing type) |

Metalization | Al | Improvement of adherability between plastic film and aluminum | Metallic yarn, Packages, Telecommunication device |

| TFM - 4102 (non-yellowing type) |

Sn | Improvement adherability between plastic film and Sn | Electric appliances, Mobile phone, Personal computer (corresponding type with damage by electrostatic discharge) |

|

| L - 140 PP primer | Plastic molding | PP | Improvement of adherability to PP substrate | Cosmetics container |

| L - 130 PET primer | PET | Improvement of adherability to PET substrate | PET | |

| TFM - 3201 | Coating surface | Coating | Improvement of printability by coating | - |

| TFM - 3103 | UV coating surface |

UV Coating | Improvement of adherability to UV hard coating | - |

The above foil grades represent only a portion of our product range.

If you have questions or a specific request,our customer service is available to help you select the right formulation for your specific application.Please contact us today.